PRODUCT

OCT OIL BOOM

Effective and fast oil spill protection.

Easy to operate by a small number of non-professionals.

No heavy machinery needed.

No maintenance once launched in the water.

Cost effective.

Easy and effective storage.

About The product

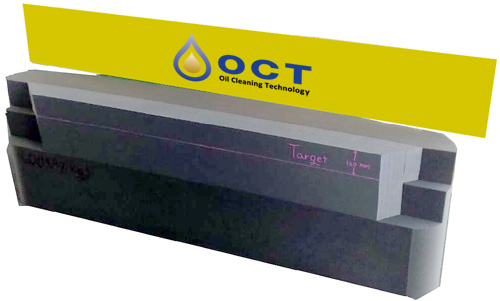

The OCT Block is made of foam with an uniquely designed cell-structure for the purpose of optimizing the booms water absorption abilities, sea positioning and protection capabilities. The patented system enables the OCT Block to absorb water increasing its weight by more than 5 000% and size by approx. 10%

The OCT Block is made of foam with an uniquely designed cell-structure for the purpose of optimizing the booms water absorption abilities, sea positioning and protection capabilities. The patented system enables the OCT Block to absorb water increasing its weight by more than 5 000% and size by approx. 10%

The OCT Block consists of different cell-structures enabling its various parts to absorb different amount of water. This optimizes the OCT Blocks behaviour and steadiness and in sea. The OCT Blocks are linked together with connecting straps with hooks that runs throughout each OCT Block.

The system is extremely flexible and may be mounted at any length desirable. After launching, the boom will be fully operational, requiring a minimum of monitoring and is not dependent on any other technical equipment.

The low weight at dry condition makes it easy for a very limited number of nonprofessionals to prepare and launch the boom into water. No heavy machinery is needed. When vacuumed-packed, a 20/40 foot container can store OCT Blocks enough to create up to approx. a 1350 / 2700 meters boom.

The OCT Block is environmentally safe and made of a solid material with “long life”, both in stored condition and in water.

Construction & Build Up

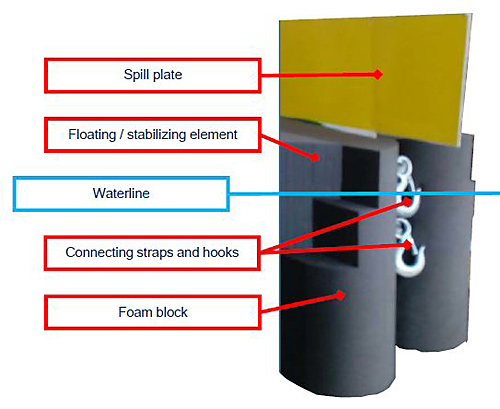

The OCT Block consist of four parts:

The OCT Block consist of four parts:

Spill-plate

It’s function is to prevent oil splash to pass the boom.

Floating / stabilizing element

Made of a closed-cell foam. Will not absorb water and makes the boom stable and floating.

Connecting straps and hooks

Connects the OCT Blocks and create a boom with no length barriers. The two straps can be delivered in different strength depending on use and needs. The OCT Blocks are connected with the hooks.

Foam block

Absorb water (not oil). Made of foam with an open cell structure.This part of the boom creates a “wall of water under water”, which means that the boom does not represent a foreign element in the water / sea.

Connecting method

The OCT Blocks are easily connected with the connection straps and the pre-mounted hooks.

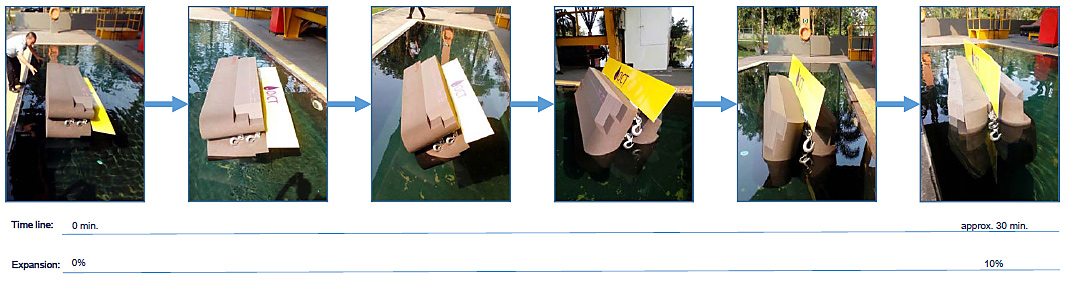

Launch process

The OCT Block rotates as it absorbers water in the open cell structure, weight in dry condition increases more than 5 000% after launched. The closed cell structure keeps the OCT Block floating and in a steady position in the water. After expanding 10% in all directions, it creates a “wall of water under water” once linked together.

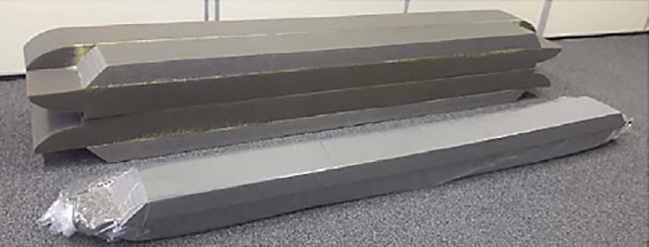

Package & Storage

One important attribute of the OCT Blocks is that it can Package & Storingbe vacuumed packed and reduced in thickness up to 75% of its original size. Effective and optimal storage and a great advantage when transporting the boom to the site. Can also be stored in depots where oil/contamination hazard is a risk. The boom can be stored for a long period of time due to the vacuumation and sealing. The plastic wrapping is easily removed by the inbuilt kevlar strap. Also, a specially design knife is made for back-up.

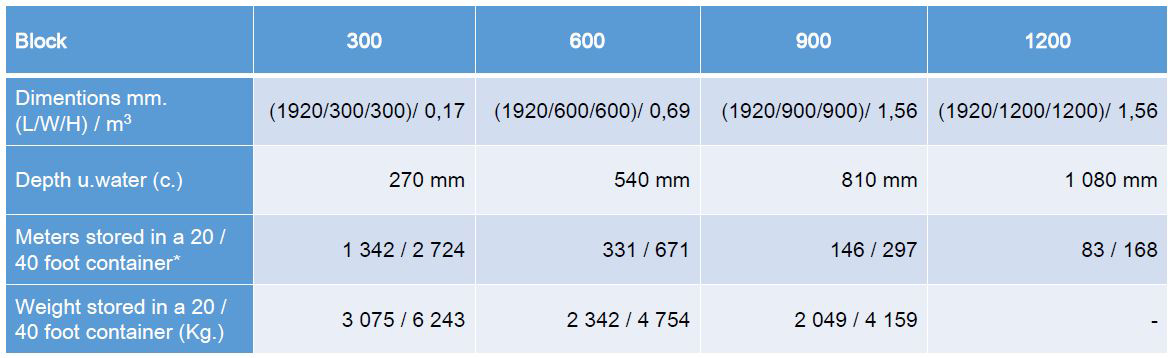

Models

OCT offers four different block sizes with different characteristics for different use:

The OCT Blocks are design for different usage depending on weather/wind conditions and type of contamination. The 1200 OCT Block is designed to be used in harsh waters and the Arctics.

USAGE SCENARIOS

The OCT Booms are very effective for fast ast oil spill protection. They are easy to operate by a small number of non-professionals.

No heavy machinery needed. No maintenance once launched in the water. See different usage scenarios below.

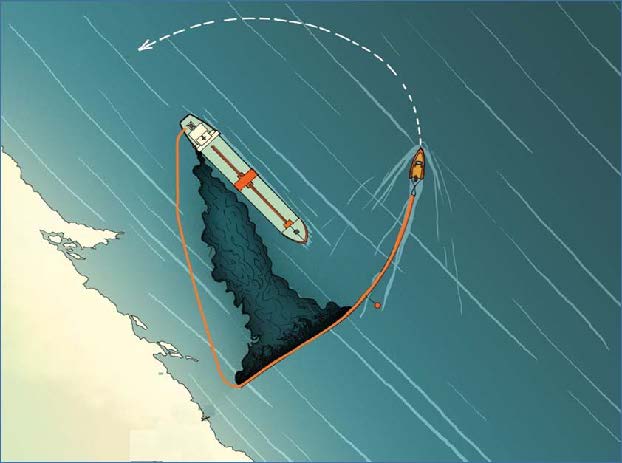

Ship scenario

OCT Booms are packed in a container and are stationary on-board the ship. In the event of an accident, the crew uses a tender to launch the OCT Boom around the ship. As the OCT Blocks absorb water, it creates a “wall of water under water” around the ship and prevents any oil spill in surrounding areas until skimmer equipment is on sight.

Shore scenario

In the event that the ship does not have OCT Boom on-board, the OCT Boom can easily be launched from land.

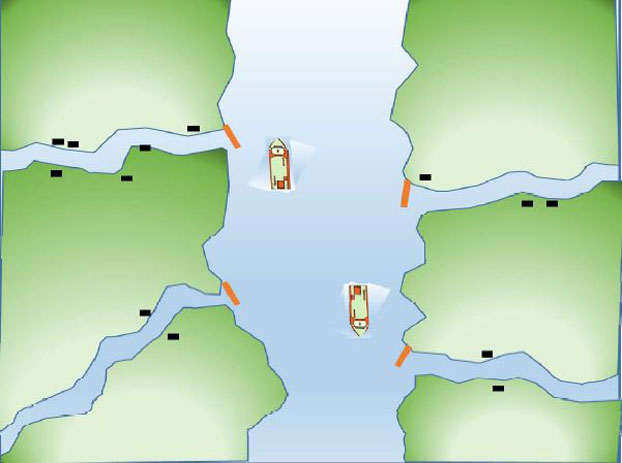

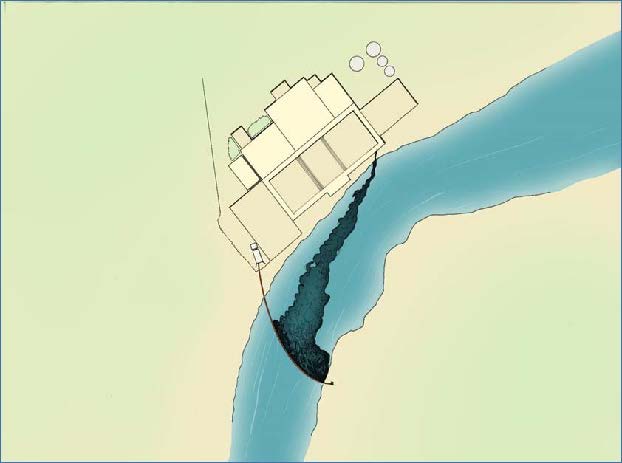

Rivers scenario

OCT Booms are set out on a more permanent basis at estuary's of side rivers (orange colour on figure = booms).OCT Booms are put down-stream to prevent contaminated water from the main river entering the side rivers. The OCT Booms are fixed to land and anchored or moored in the river to keep the O.C.T Boom in position.

River scenario 2

OCT Booms are stored on a more permanent basis by factories etc. that can represent a contamination hazard. In the event of an accident, the OCT Boom is launched across the river to avoid any contamination to flow freely downstream. The OCT Booms are launched by using light machinery (tender, winch etc.) or by man power pulling the O.C.T Boom across the river.

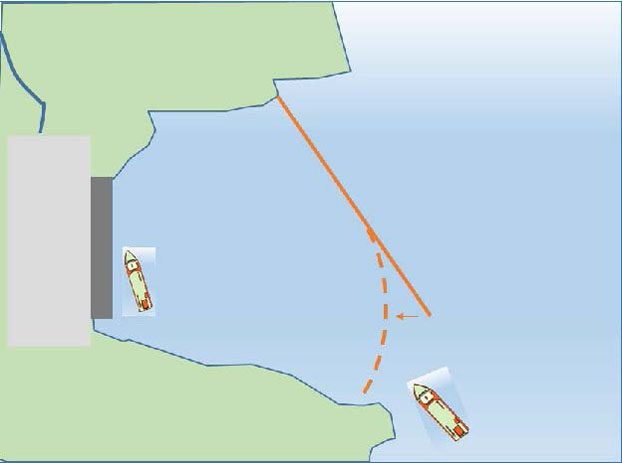

Harbor scenario

An OCT Boom is launched permanently at the harbour area. In the event of an accident, the permanent OCT Boom is dragged from its original position and fixed to land (dotted line on the figure) in order to seal of the area.

Platform scenario

OCT Booms are packed in a container or stored on the platform on a permanent basis. In the event of a accident, the crew uses a tender to launch the OCT Boom around the platform. As the O.C.T Boom absorbs water, it creates a “wall of water under water” around the platform and prevents any oil spill in surrounding areas until skimmer equipment is on sight.